Ivor King are industry leaders in Giken SuperCrush piling techniques

Last month, we highlighted the benefits of Silent & Vibration-free Sheet Pile Installation using a Giken Silent Piler. This month, we take a closer look at Giken SuperCrush — a revolutionary installation technique that pushes the boundaries of what’s possible in vibrationless silent sheet piling, even in the toughest ground conditions.

What is Giken SuperCrush?

The Giken SuperCrush system is a specialised and highly advanced form of silent piling, designed to tackle some of the most difficult geotechnical conditions — including dense soils, obstructions, and even rock.

Unlike traditional methods of impact or vibration piling, SuperCrush operates entirely without vibration, making it exceptionally well-suited to sensitive or restricted sites such as urban areas, heritage zones, and environmentally protected areas.

The process combines hydraulic press-in technology with a high-torque auger system that pre-augers the soil immediately ahead of the pile toe. This creates an engineered path, significantly reducing resistance and allowing sheet piles to be installed with precision and control.

Proven Performance in Demanding Conditions

Ivor King is proud to be the UK’s largest owner and operator of Giken Silent Piling equipment — including a robust fleet of SuperCrush-capable units.

We have the capacity to install:

- U and Z section sheet piles

- Pairs of Z piles up to 1.4m wide

- Pile depths of up to 24 metres, subject to pile length availability and site conditions

This makes our SuperCrush offering an ideal solution for everything from basement construction and infrastructure upgrades to retaining walls and coastal defence works in challenging terrain.rd ground and rock formations.

How It Works

The Giken SuperCrush method works on a press-in principle, using the reaction force of previously installed piles to drive the next. As the auger cuts through obstructions and dense material, the pile is simultaneously pushed into place, creating a smooth, controlled installation process.

With no vibration and ultra-low noise, this method is ideal for sites where disruption must be minimised — including:

- Town & City centre developments

- Road & Rail infrastructure

- Historic and listed structures

- Environmentally sensitive locations

Soil displacement is carefully managed throughout the process, helping to maintain ground stability and minimise surface settlement or movement.

Giken SuperCrush is an advanced press-in piling system designed to install interlocking sheet piles into hard ground, with ultra-low noise levels and without any vibration.

The Giken SuperCrush method works on a press-in principle, using the reaction force of previously installed piles to drive the next.

Unlike traditional impact or vibratory methods, it uses the dual-action of hydraulic force and simultaneous augering to press piles into hard ground conditions with minimal disruption – ideal for urban, noise-sensitive, or fragile environments.

SuperCrush piling is commonly used in infrastructure projects, urban developments, heritage sites, flood defences, and other locations where traditional piling methods might cause disruption or risk damage to nearby structures.

Unlike vibrating pile drivers that use high-frequency oscillations – which cause noise, ground disturbance, and sometimes structural risk – the Giken system presses piles silently and without vibration. Giken piling is therefore safer and more suitable for sites near existing buildings or in environmentally sensitive areas. It’s powerful yet compact, and offers an incredibly eco-friendly solution.

Absolutely. SuperCrush mode is an extension of Giken sheet piling, specifically designed for hard ground conditions, up to and including solid rock. The integrated auger drills through obstructions or dense soils ahead of the pile, allowing smooth, controlled installation even in challenging subsurface conditions.

A Partner in Precision

Our relationship with Giken goes far beyond the machines. As part of the Giken Total Support System (GTOSS), our team benefits from ongoing technical training and support direct from Giken Europe, ensuring each project is delivered with world-class accuracy, safety, and technical confidence.

Why Choose Giken SuperCrush with Ivor King?

✅ Unrivalled UK experience operating Giken SuperCrush systems

✅ Fleet of SuperCrush units ready for deployment nationwide and beyond

✅ Delivers a Silent & vibration-free installation into hard ground — ideal for sensitive or constrained sites

✅ In-house Design & Estimating team to tailor solutions for even the most complex geotechnical challenges

From the smallest machines in our fleet, the compact but powerful F201, with 150 tonnes of pressing force, up to our SCZ675 Silent Pilers, capable of installing a pair of Z piles simultaneously, enabling a 1.4m section to be pressed. Our fleet of Giken Silent Pilers with SuperCrush capability offers a broad range of equipment, depending on the specific demands of the site and ground conditions.

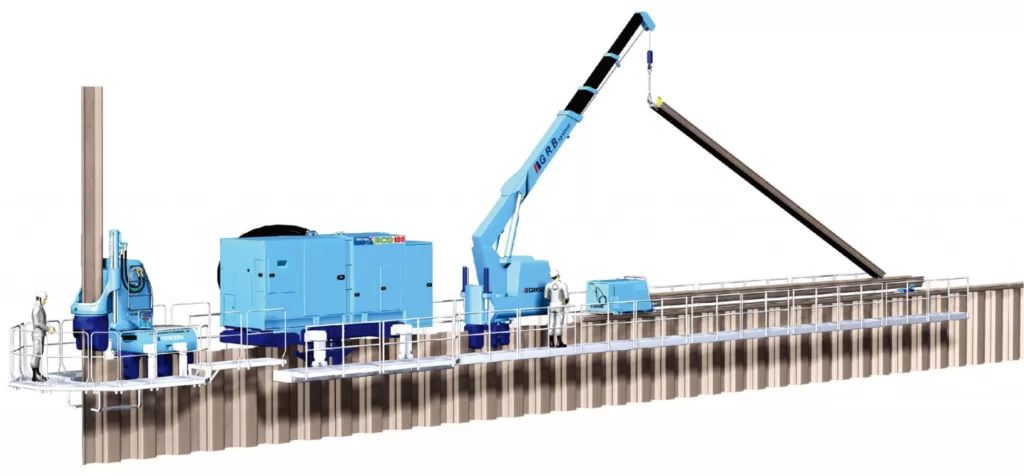

For sites with extremely limited access, we can also offer the Full GRB (Giken Reaction Base) System, which works on the principle of a footprint free installation. That is to say all piling procedures, including pile transportation, pile pitching and press-in work are possible from on top of installed piles. See a video of our GRB System in action HERE.

Need advice on whether Giken SuperCrush Silent & Vibrationless Piling is right for your project?

Ivor King has over 50 years of experience in steel sheet piling, we specialise in providing innovative and bespoke piling solutions.

If your project requires silent, vibration-free piling in challenging ground conditions, the Giken SuperCrush system — backed by Ivor King’s unmatched expertise — delivers a proven, precision-engineered solution.

Take a look at the range of Steel Piling Solutions we can design and install, and get in touch with our knowledgeable and friendly team to discuss how we can help. Whatever your piling project, we’re your people.

Sheet Pile Retaining Walls

The quick and easy solution that eliminates the need for temporary earthworks support.

Sheet Pile Basements

Maximise your basement footprint with a cost effective watertight construction solution.

Cofferdams

Allows excavation and construction in otherwise poor working environments

Temporary Sheet Pile Walls

Allowing earthworks to take place, sheet piles can be re-used on project completion

Steel Bearing Pile Foundations

Providing excellent load and resistance and high strength in compression and tension

Tied Walls & Anchorage Systems

Sheet pile walls can be strengthened using anchorage systems to ensure the stability of retaining structures

Inland Waterways & Marine Piling Solutions

Flood defences and water retention systems, including rivers, canals, harbour and dock wall stabilisations, marinas and reservoirs

Sheet Pile Hire & Sales Our dedicated hire and sales division is on hand to support all your temporary and permanent sheet pile needs