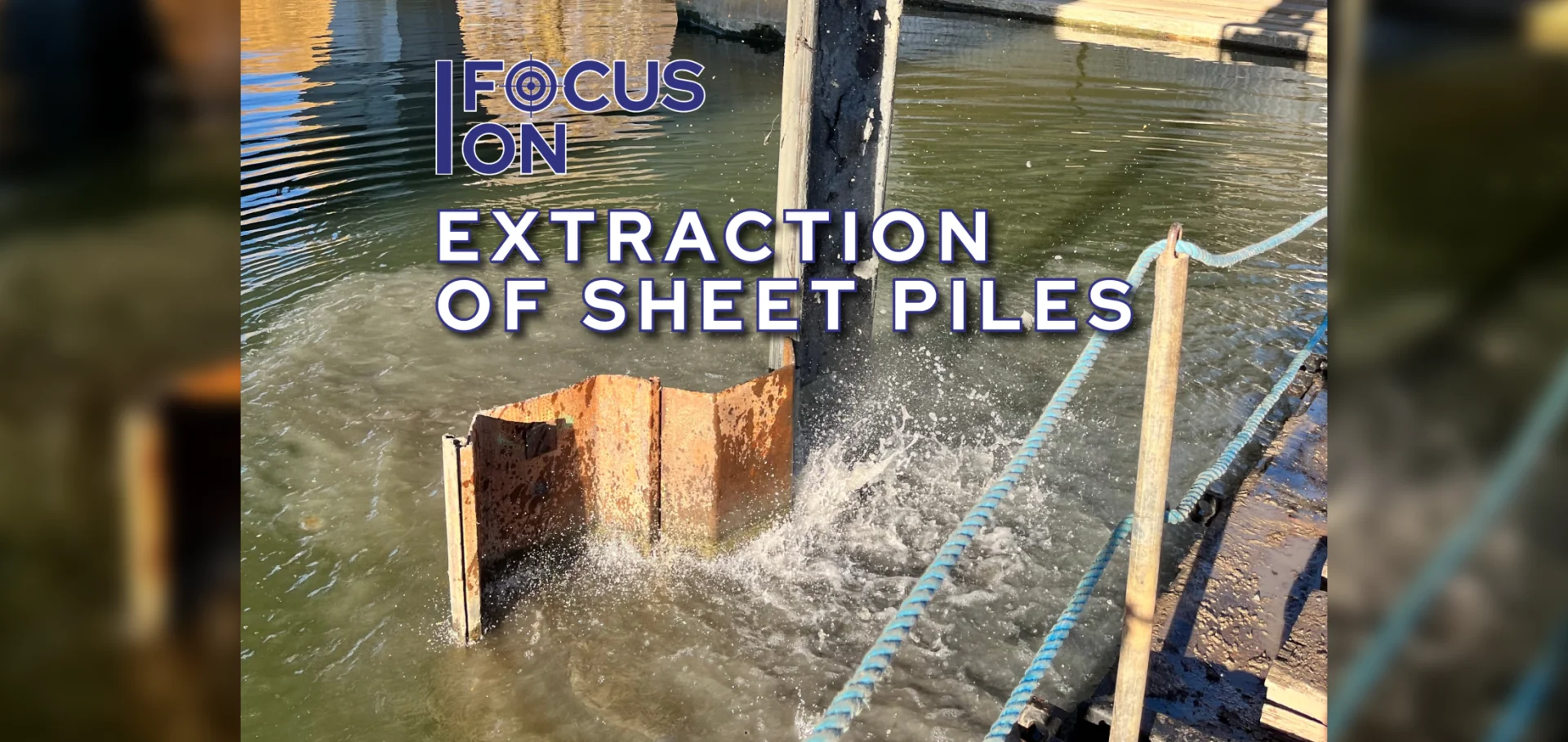

Sheet Pile Extraction: What we do – and how we do it

Sheet pile extraction, sometimes referred to as pile pulling, is the reverse process of sheet pile installation. It plays a crucial role in temporary works, where steel sheet piles provide essential stability during construction but are later removed once their job is complete.

Steel sheet piling is one of the most flexible, cost-effective, and sustainable solutions in modern construction. Not only do sheet piles create safe working conditions during the build phase, they can also be reused following extraction, helping to minimise waste and reduce the overall carbon footprint of a project.

How Sheet Piles Are Used in Temporary Works

One of the most common temporary applications is the construction of a sheet piled cofferdam. This method allows contractors to work safely in dry, stable conditions below ground or even below water level. The cofferdam sheet piling process typically involves four stages:

- Sheet Pile Installation – Steel sheet piles are driven or pressed into the ground to create a secure barrier.

- Excavation – The enclosed area is excavated to provide access for underground works such as basements, foundations, or utilities.

- Completion and Backfilling – Once construction is complete, the excavation is backfilled up to ground level.

- Pile Extraction (Pile Pulling) – The temporary sheet piling is carefully removed, leaving no permanent structure behind and restoring the site.

For temporary works, U-profile sheet piles are often preferred, as they tend to drive, extract, and stack more efficiently than Z-sections, with reduced risk of pile damage. That said, Z-sections can still be used effectively where project requirements call for them.

Methods of Sheet Pile Extraction

Extracting piles requires just as much expertise as installing them. Each site presents unique challenges, and the choice of pile extraction method depends on factors such as soil type, pile length, access, and environmental considerations.

Vibratory Extraction

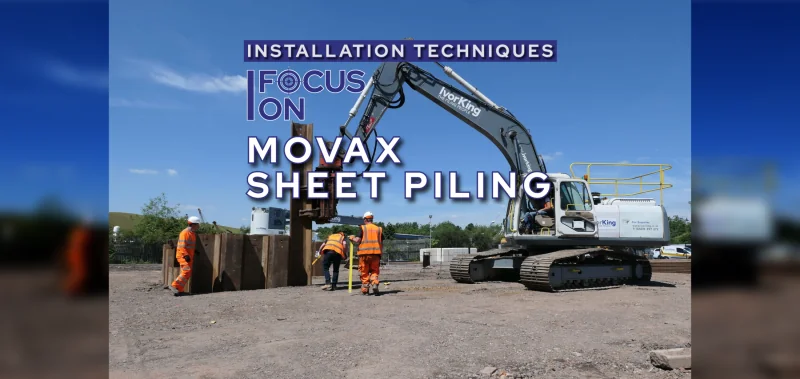

- Excavator-Mounted Vibro Hammers (Movax) – Compact and versatile, these units are highly effective for smaller sites and make use of the Movax ‘side grip’ technology for handling of sheet piles

- Telescopic Leader Rigs – Provide stability and precision, using vibration to release piles efficiently.

- Crane-Suspended Vibro Hammers – Suited to marine or over-water environments where rigs and excavators have limited access.

These methods work by vibrating the pile and surrounding soil to reduce resistance, allowing piles to be loosened and removed.

Silent Extraction

In noise-sensitive or vibration-restricted environments, the Giken Silent Piler provides an alternative. Using hydraulic rams, the system applies up to 150 tonnes of pulling force on a single pile, extracting without noise or vibration. Because the Giken sits on top of the installed piles, it can self-travel along the line, making it ideal for:

- Urban and city centre projects

- Historic and heritage-sensitive sites

- Rail and infrastructure works

- Sloping or restricted-access ground

- Over-water applications where pontoons are impractical

Additional Support Techniques

In some cases, water jetting or localised excavation is used to assist pile removal, particularly in dense or challenging ground conditions.

Sustainability in Action – Steel Sheet Pile Reuse

Once extracted, sheet piles can be reused. At Ivor King, all piles are returned to our central hub, where they are cleaned, trimmed if required, and re-stocked for future use. With over 3,000 tonnes of sheet piles in continuous stock, we can provide quick turnaround supply for both hire and purchase.

This cycle of installation, extraction, and reuse makes sheet piling one of the most sustainable forms of temporary works in civil engineering.

In Summary

Sheet pile extraction is more than just ‘pulling piles.’ It’s a carefully planned operation that balances safety, precision, and environmental responsibility. Whether your project calls for vibratory methods, or silent piler based installation and extraction, Ivor King has the equipment, expertise, and stock to deliver.

Sheet pile extraction allows steel piles to be recovered and reused, rather than discarded after a project. By reusing piles, contractors reduce material waste and significantly cut the carbon footprint of temporary works. This makes extraction an important step in building more sustainable construction practices.

The most common method is vibratory extraction, using specialist equipment such as Movax side-grip or Leader Rigs. Where noise and vibration must be minimised, silent extraction with a Giken silent piler is preferred. In more challenging conditions, assisted techniques like water jetting or localised excavation can also be used to free sheet piles.

A Giken silent piler is best suited for sensitive sites where vibration or noise could cause disruption or damage. This includes working near heritage structures, in residential areas, or on projects with restricted access. Vibro hammers are effective on less sensitive sites, but the Giken provides a quiet, non-disruptive alternative.

Yes! Steel sheet piles can be cleaned, trimmed, and re-stocked for use on future projects. This reuse not only reduces costs for contractors but also supports more sustainable construction practices by extending the lifecycle of the material. At Ivor King, we maintain a large stock of reusable sheet piles available for both hire and sale.

Ivor King offers a versatile fleet of extraction equipment, extensive stock availability, and decades of expertise in piling and extraction. Our experienced team delivers tailored solutions for projects of all sizes, ensuring efficiency, safety, and sustainability. With flexible hire, sale, and service options, we’re the trusted partner for sheet pile extraction across the UK.

Capability coupled with experience

✅ Ivor King owns an extensive fleet of vibratory and silent installation and extraction equipment

✅ We have over 3,000 tonnes of sheet piles in stock for immediate hire or sale

✅ Our equipment is available for hire UK-wide and overseas, with or without skilled operators

✅ We offer flexible support to provide as much or as little resource as your project requires

Ivor King has over 50 years of experience in steel sheet piling, we specialise in providing innovative and bespoke piling solutions.

Take a look at the range of Steel Piling Solutions we can design, install, and extract and get in touch with our knowledgeable and friendly team to discuss how we can help. Whatever your piling project, we’re your people.

Sheet Pile Retaining Walls

The quick and easy solution that eliminates the need for temporary earthworks support.

Sheet Pile Basements

Maximise your basement footprint with a cost effective watertight construction solution.

Cofferdams

Allows excavation and construction in otherwise poor working environments

Temporary Sheet Pile Walls

Allowing earthworks to take place, sheet piles can be re-used on project completion

Steel Bearing Pile Foundations

Providing excellent load and resistance and high strength in compression and tension

Ground Anchors

Economical and practical alternative to propping, enabling greater retained heights

Inland Waterways & Marine Piling Solutions

Flood defences and water retention systems, including rivers, canals, harbour and dock wall stabilisations, marinas and reservoirs

Sheet Pile Hire & Sales Our dedicated hire and sales division is on hand to support all your temporary and permanent sheet pile needs